Knowledge

What Is The Press Fit Force

What Is The Press Fit Force

Noun Explanation

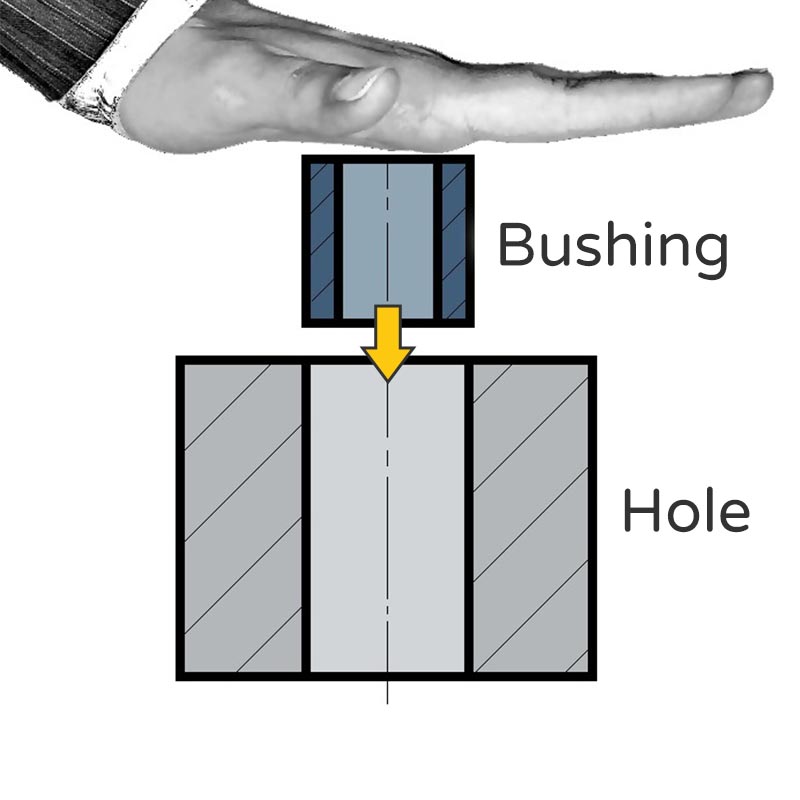

The so-called “Press” refers to the force from top to bottom. For example: ① Imagine people pressing them with their hands. ② Pressure cookers use steam to quickly cook food.

The so-called “Fit” refers to matching and assembling. When two objects are combined without using other items such as glue, screws, etc., they must use themselves to combine. What we are talking about will be interference fit (tight fit), because if there is no interference, there will be no press fit force, and they will be able to move freely relative to each other.

Although everyone may have different opinions, the word “press fit” can make people have a deeper impression and association. Therefore, press fit refers to the force required to install the bearing into the hole or shaft until it is positioned.

Other terms

Assembly force, press-in force, installation force, interference force… and so on.

The purpose of press-fit force

When talking about “press-fit force,” most people focus on assembly difficulty and work efficiency. The press-fit force refers to the downward pressure applied, and if it exceeds what an average person can exert, it can lead to operator fatigue and injury. Given the need for frequent operations, mechanical force arms or fully automated pressurization systems are often necessary to assist in the assembly. In some product designs, the press-fit force for bushings can even exceed 400 kg.

What are the main factors that influence it?

During the bearing assembly process, the main reasons that affect the size of the press-fit force are as follows:

- The strength of the material is proportional to the bearing material’s ability to resist deformation. Different materials have different strengths.

- Thickness (wall thickness) is proportional. Subtract the outer diameter from the inner diameter of the bearing and divide by 2 to get the thickness, that is, the single-side wall thickness. The greater the thickness, the higher the strength, but it will reach a nearly saturated and balanced state. It does not mean that infinite thickness means infinite strength.

- Contact area is proportional to the total surface area of contact between the bearing and the hole. Here, the emphasis is on diameter. Under the same conditions, a bearing with a larger diameter will be more difficult to install than a bearing with a smaller diameter.

- The contact height is proportional. Increasing the height of the bearing is equivalent to increasing the contact area.

- Interference is proportional to the value of interference fit. If the bearing is installed in a hole, the outer diameter of the bearing must be larger than the size of the hole.

- The coefficient of friction is proportional to the friction between two objects when they slide against each other on the contact surface. The smoothness and cleanliness of the surface and whether lubricants are added will affect the coefficient of friction.

For example: A designer considers that during assembly, the assemblers should press and fit objects in the most labor-saving way, but how to achieve this? You can apply a little lubricant in the hole to reduce the friction coefficient between the two objects, or you can reduce the height of the bearing.

Secondary factors

A common but important consideration is to ensure that all parts are clean, free of impurities, and not damaged or worn. Any dirt or debris may affect the press-fit force, which is the force required for installation.

In addition, during the installation process, put it in as straight as possible, and do not assemble it at an angle exceeding a certain degree. The applied force must be evenly distributed to avoid excessive force on one side, which may cause fatigue damage to the bearing material. This incorrect method will also affect the value of the press-fit force.

Difference from Pull-Off Force

The difference is that the direction of force is opposite, and the purpose of consideration is different. In principle, the force value can be considered the same. The difference between the two is as follows:

The press-fit force is the value obtained through the machine test. It belongs to the dynamic friction coefficient. It is the friction force that needs to be overcome during sliding. The measured data is the final force before the bearing stops. As the depth of the bushing is pressed deeper, the contact area will gradually increase, and the force will be greater.

On the contrary, the pull-out force belongs to the static friction coefficient. It takes a greater force to overcome static friction and make the object start moving. The measured data is the initial force once the bearing moves. As the bushing is withdrawn, the contact area will gradually decrease and the force will become smaller.

Since the static friction coefficient is greater than the dynamic friction coefficient, theoretically, the measured pull-out force will be slightly greater than the press-fit force. After understanding the difference between the static and dynamic friction coefficients, generally speaking, if you don’t care about the small difference, you can regard them as equal.

How do you know what the Press-Fit Force is?

First of all, it is better to rely on the test machine to obtain the data, which is in line with actual use and true. If there is really no equipment to obtain this information, we provide online calculation of the theoretical value of the press-fit force (pull-off force). You only need to fill in a few dimensions. Please click the following link: