Knowledge

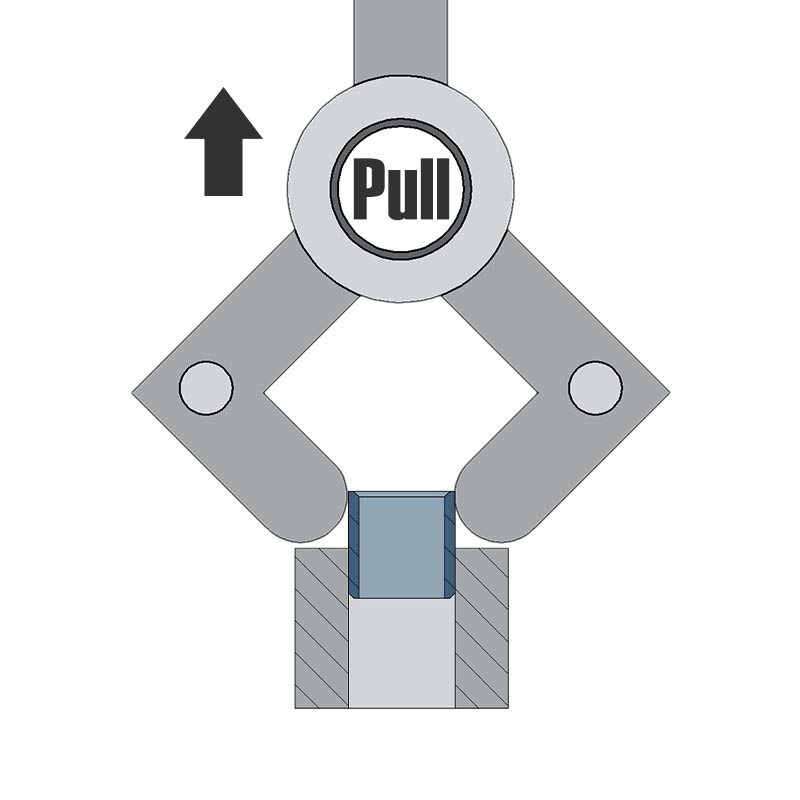

What Is Pull-off Force?

What Is Pull-off Force

Noun Explanation

Pull, refers to the force of pulling out and extracting from bottom to top.

To loosen, withdraw, or remove two objects that have been combined. All of the above will be interference fit (tight fit), because if there is no interference, there will be no Pull-off Force, and they will be able to move freely relative to each other.

Therefore, the definition of bushing Pull-out Force is the force required to completely Pull out the installed bushing from the hole or shaft.

Other terms

Pull-out Force, Interference Force… and so on.

Purpose of Pull-off Force

Generally speaking, when discussing “Pull-off Force”, most people consider “to prevent it from falling off or being displaced”. When the bushing is installed in a rotating and sliding mechanism, there may be vibrations from the operation of the engine machinery, axial lateral force contact friction, etc., especially sliding friction. Depending on the size of the lateral force, if the Pull-off Force is not sufficient, the bearing will be displaced or even fall off, causing damage to product parts.

What factors will affect it?

During the bearing assembly process, the main reasons that affect the pull-out force are:

- The strength of the material is proportional to the bearing material’s ability to resist deformation. Different materials have different strengths.

- Thickness (wall thickness) is proportional. Subtract the outer diameter from the inner diameter of the bearing and divide by 2 to get the thickness, that is, the single-side wall thickness. The greater the thickness, the higher the strength, but it will reach a nearly saturated and balanced state. It does not mean that infinite thickness means infinite strength.

- Contact area is proportional to the total surface area of contact between the bearing and the hole. Here, the emphasis is on diameter. Under the same conditions, a bearing with a larger diameter will be more difficult to install than a bearing with a smaller diameter.

- The contact height is proportional. Increasing the height of the bearing is equivalent to increasing the contact area.

- Interference is proportional to the value of interference fit. If the bearing is installed in a hole, the outer diameter of the bearing must be larger than the size of the hole.

- The coefficient of friction is proportional to the friction between two objects when they slide against each other on the contact surface. The smoothness and cleanliness of the surface and whether lubricants are added will affect the coefficient of friction.

For example, if you want to remove the bearing from the hole, spray a highly fluid lubricant and allow it to penetrate as much as possible into the gap between the contact surface of the bearing and the hole to make it easier to pull the bearing out.

Suggestion

In short, if there’s still room in the design, physical methods can be used to keep the bearing from falling off or shifting. Relying only on pulling force to hold it in place is often insufficient, particularly in cases of mechanical vibrations or sudden lateral impacts. Examples like C-rings, grooves, and retaining walls can effectively prevent the bearing from moving.

Other environmental factors

When testing the Pull-off Force, the data is measured based on the set conditions. Although the data is accurate, it is different from the actual usage conditions. Therefore, the following two points still need to be taken into consideration, otherwise the pull-off will still occur.

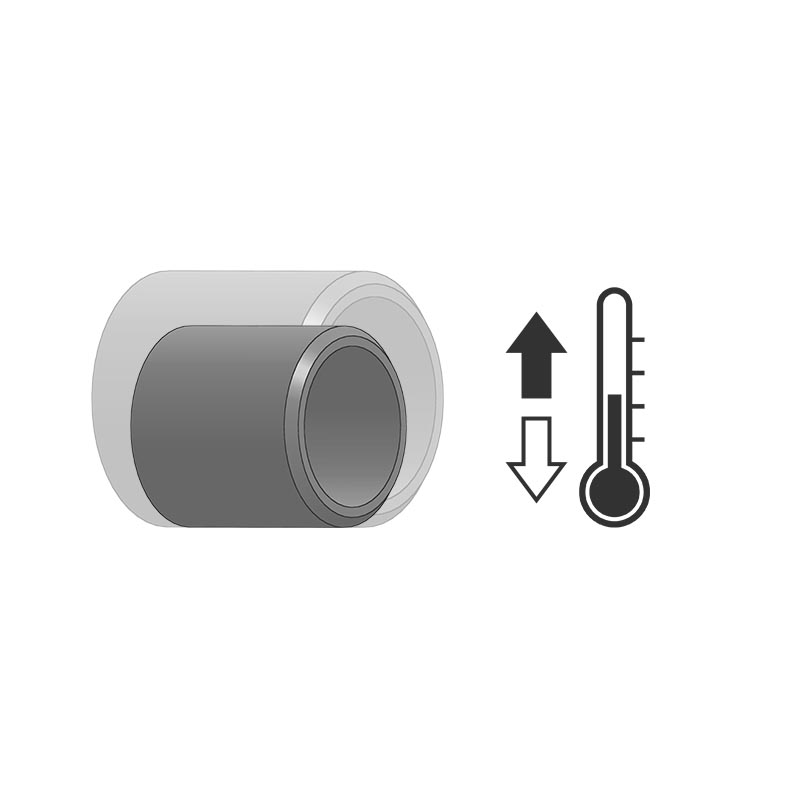

Thermal expansion and contraction

The linear expansion coefficient of plastic materials is larger than that of metals, which is 4 to 10 times different from that of metal materials. Therefore, the phenomenon of thermal expansion and contraction is obvious.

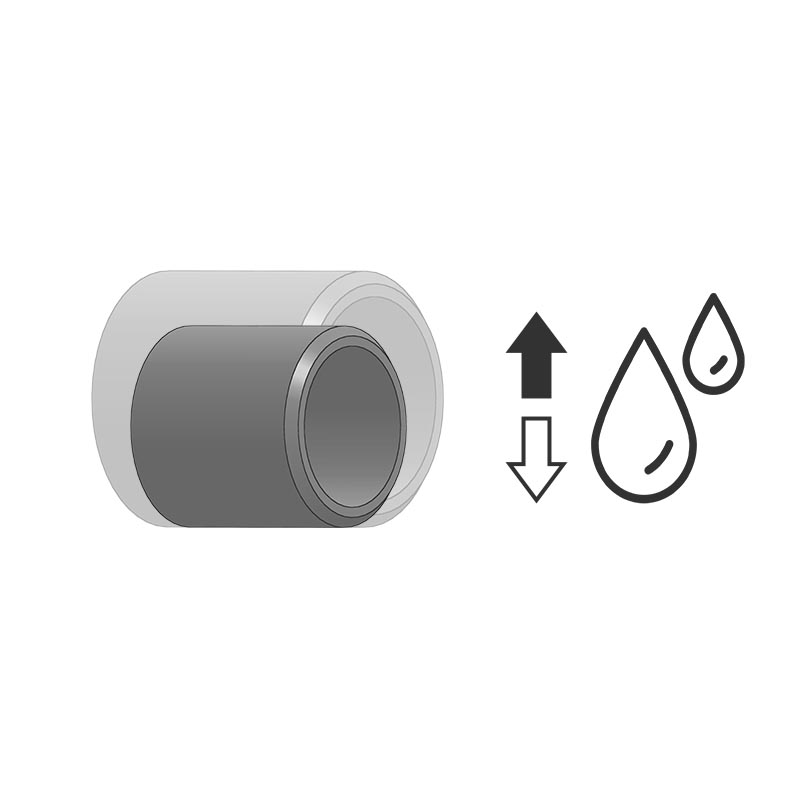

Moisture absorption

The plastic material absorbs water, and its size will change slightly. When it reaches equilibrium with the atmospheric moisture, it will stabilize.

It changes with the humidity and water vapor in the atmospheric environment, and stabilizes when it reaches equilibrium with the atmospheric humidity.

Difference from Press Fit Force

The difference is that the direction of force is opposite, and the purpose of consideration is different. In principle, the force value can be considered the same. The difference between the two is as follows:

The press-fit force is the value obtained through the machine test. It belongs to the dynamic friction coefficient. It is the friction force that needs to be overcome during sliding. The measured data is the final force before the bearing stops. As the depth of the bushing is pressed deeper, the contact area will gradually increase, and the force will be greater.

On the contrary, the pull-out force belongs to the static friction coefficient. It takes a greater force to overcome static friction and make the object start moving. The measured data is the initial force once the bearing moves. As the bushing is withdrawn, the contact area will gradually decrease and the force will become smaller.

Since the static friction coefficient is greater than the dynamic friction coefficient, theoretically, the measured pull-out force will be slightly greater than the press-fit force. After understanding the difference between the static and dynamic friction coefficients, generally speaking, if you don’t care about the small difference, you can regard them as equal.

How do you know what the Pull-off Force is?

First of all, it is better to rely on the test machine to obtain the data, which is in line with actual use and true. If there is really no equipment to obtain this information, we provide online calculation of the theoretical value of the press-fit force (pull-off force). You only need to fill in a few dimensions. Please click the following link: