Knowledge

What are the types of wear, friction is briefly discussed

What are the types of Wear?

This article is more professional, share some of my own experience, because the wear and tear situation is quite complex, unable to be fully explained, and there is no standard answer, so it is for reference only.

What you think is the general rule of wear and tear may not be realized

When observing the surface of abrasive materials, we can understand the types of wear surfaces, which have different names depending on the type of friction, and can be divided into the following basic categories. Generally speaking, even if it belongs to this single wear category, there are still other types of wear, and most of them will be a comprehensive type of wear. Therefore, when classifying grinding types, special attention should be paid to the main causes of wear.

Adhesive wear

Also known as attachment wear, wear is caused by the damage of the attachment bond at the real contact site. Adhesive wear causes increased roughness and the creation of protrusions (i.e., lumps) on the surface.

Complex wear

The situation of Adhesive wear is quite complex in terms of structure. If there is shear at the adhesive bonding part of A and B in the state of mutual friction, even if there is shear at part A, if the sheared part A is still attached to B, there will be no abrasion powder. It can be said that it is transferred from A to B, and again, in the process of wearing, the A part that has been transferred to B and then transferred back to A, the so-called reverse transfer, the whole process, may be repeated, may not be.

Then, the wear from parts A and B gradually becomes larger between the adhesive and friction surfaces, and is discharged out of the friction surface. Therefore, the size of the abrasive dust discharged to the outside is not directly related to the size of the friction surface, that is, the contact surface and the sliding distance.

Adhesive wear of metals

The adhesion and wear of metals is affected by the difficulty of two metals rubbing against each other to become alloys, and instantaneous microwelding may occur due to the heat generated by the friction. If it is a metal with strong compatibility, it is easy to produce strong adhesion and therefore SCUFFING.

Between the metals, under sufficient lubrication, the machine elements operate smoothly and reduce the wear rate. When lubrication fails, parts can cause destructive friction against each other, leading to heating, localized welding, destructive damage, and failure. For example, stainless steel 304 is likely to transfer material when sliding, resulting in serious surface damage.

The main function of the car is to reduce the friction and wear of parts, and the oil needs to be changed regularly to avoid excessive adhesion and wear accumulation.

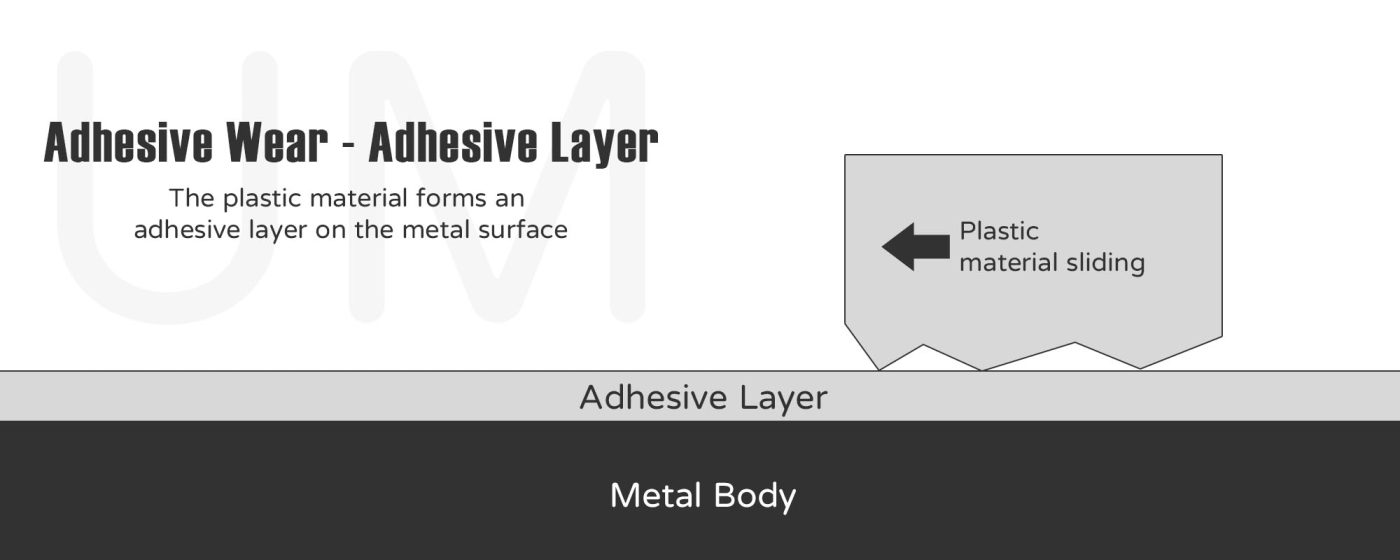

Adhesive layer of plastic

Adhesive layer, or transfer layer or transfer membrane. No matter what kind of plastic, once rubbed repeatedly, it can form an adhesive layer on the surface of the opponent, forming a sliding layer on the adhesion layer, which is generally regarded as helping to reduce friction and wear, which means that the wear rate of the same type of materials is smaller when they slide against each other. Once the adhesive layer is removed by various factors, such as foreign sand and dust particles forming three-body scraping friction, the adhesive layer is removed, thus forming wear.

If it is HDPE or nylon material, when the initial wear state of the transfer layer is fully formed, the wear rate is larger, and after becoming a fixed wear state, the wear rate is smaller than the initial wear state, but if it is PTFE, it is not necessarily so.

What factors can cause adhesive wear?

Before explaining these factors, it is necessary to let the reader understand one thing, which is that there is no absolute answer, because the factors affecting wear and tear are very complex, and often in experiments, under the law of wear, there are still situations that cannot be established. However, we still provide a few directions for your reference.

- The higher the hardness of the material, the less adhesion and wear it will be, but it is easy to damage the opponent part, in other words, it will scrape off the opponent part. On the contrary, the lower the hardness of the material, the more adhesive wear and tear, and it is also easy to be damaged by the opponent’s parts.

- The faster the sliding speed, the more adhesive wear and tear, but the less impact compared to the load.

- The greater the load, the more adhesive wear and tear.

- The larger the contact area, the more adhesive wear and tear.

- Adaptability when the material rubs between two bodies, or intercompatibility.

- The closer you are to the maximum temperature of the material, the more adhesive wear will be.

Abrasion

Also known as abrasive wear, or abrasive wear, material loss caused by raised parts or hard particles on a hard surface and moving along a solid surface, resulting in a small cutting effect.

This occurs when a hard, rough surface moves towards a softer surface. Harder materials may be just one of these cases, or they may be foreign particles or particles from adhesive wear.

Abrasive wear of the two bodies

When particles, grit, and jagged teeth on a hard surface slide relative to another surface, scraping wear of two objects will occur, referred to as double wear, common examples, grinders, grinders, files.

The thicker the sandpaper, the greater the wear of the abrasive surface, and the coarser the sandpaper, the larger the abrasive particles used.

Abrasive Wear of Three bodies

Trisomy wear occurs when particles are unrestrained and freely roll and slide across the surfaces of both objects. Generally speaking, the wear rate of scraping wear will be greater than that of adhesive wear, which is very important when observing from a practical level. This is related to whether the environmental contact is or not, which determines whether the nature of wear is open or closed.

Open state

This is quite easy to understand, that is, the abrasive wear caused by mixing with the sand and dust and foreign matter in the environment, in order to avoid this problem, there will be dust cover and dust cover in the design.

Closed state – abrasive

In the state of being closed from the outside world, the wear between the two objects, any form of abrasion produces fine particles, whether it is scraping wear or adhesive wear, from the material of the two objects, that is, abrasion, and between the two objects to do friction movement, causing wear of any object. The generation of abrasive chips cannot be completely avoided, and the expedient measure is to clean or replace them regularly, example 1, the CVT transmission of the car, after a period of use, the abrasive chips inside should be cleaned through the air to reduce wear.

What factors can cause Abrasive wear?

Before explaining these factors, it is necessary to let the reader understand one thing, which is that there is no absolute answer, because the factors affecting wear and tear are very complex, and often in experiments, under the law of wear, there are still situations that cannot be established. However, we still provide a few directions for your reference

- The higher the hardness of the material, the less scraping wear will be required, but it is easy to damage the opponent part, in other words, the opponent part will be scraped. On the contrary, the lower the hardness, the more scraping and wear it will be, and it is easy to be injured by the opponent’s parts.

- The faster the sliding speed, the more scraping wear will be.

- The larger the load, the more scraping wear will be worn, but the impact of the load is less than that of the sliding speed.

- Adaptability when the material rubs between two bodies, or intercompatibility.

I believe that readers see this, do you think that improving the hardness of the material will reduce wear. For example, if plastic rubs against metal parts, increasing the hardness of the plastic may accelerate the damage to the metal, and the value (amount) of the metal is 10 times higher than that of the plastic, then increasing the hardness of the plastic becomes not worth it.

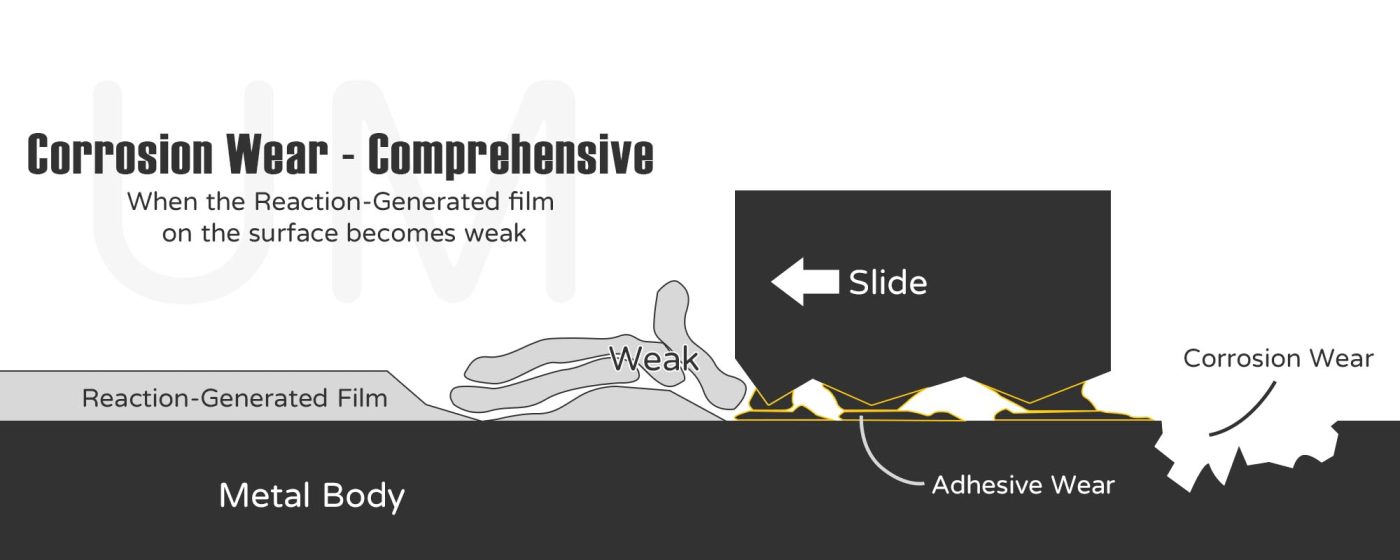

Corrosion and wear

The corrosive effect of the atmosphere or lubricant has a damaging effect on the real contact part due to friction, which affects the wear and tear when it is affected.

The atmosphere in the environment, the surrounding humidity and liquids may react chemically with the surface, resulting in wear and tear on the solid surface due to the formation of products. In terms of the occurrence process of corrosion and wear, the first stage belongs to the corrosion process (reaction process), and the second stage is to remove the reaction to form a film during the sliding process.

Explanation of proper Nouns

Various terms such as reactive formation film, protective film, lubricating film, oxide film are coming up here. For ease of interpretation, readers are invited to consider them as the same thing. Only they are nuanced, which is explained below.

- Oxide film: uncertain whether it is beneficial or harmful.

- Reaction generates membrane: a general term for a noun, but not certain beneficial or harmful.

- Protective and lubricating films: advantageous.

The First Stage, the reaction process

The smooth metal surface is easy to react with the influencing factors in the environment, and the formation is collectively known as “reaction formation film”, the initial generation speed is very fast, and the generation speed slows down as the thickness of the formed film increases.

When air reacts chemically with aluminum, the reaction stops completely as soon as an oxide film with a thickness of about 20nm is formed. Sometimes the material’s film thickens over time, for example, iron rusts and expands in volume. In addition, some oxides have a friction reduction effect.

The second stage, the clearance process

Even if the metal surface is not smooth at first, once it slides, it is affected by abrasion and makes the surface of the metal itself smooth, but there is still a certain thickness of the film residue on the metal surface.

Formation of protective film

Corroded materials undergo surface changes that form a lubricating film on the surface, which is rare if the lubricating film inhibits the effects of adhesion and corrosion.

Corrosion formation

The protective film is completely worn out, resulting in spots and potholes (pitting) on the surface.

Corrosion wear and other wear

In this case, for example, when metal comes into contact with sulfide, phosphide, etc., the reaction on the surface creates a film that becomes weaker, resulting in adhesion wear in some areas and corrosion wear in some areas.

Is there a difference between an adhesive layer and a protective layer (membrane)?

These two terms are really a bit similar and confusing. They all have functions that help reduce wear and tear, but the way they are produced is different. The adhesive layer comes from the plastic material due to adhesion and wear, forming a large amount of adhesive layer on the metal surface. The protective layer is formed by the chemical reaction between the metal surface and the atmospheric environment.

Fatigue and wear

During rolling, the stress on the contact part is repeatedly acted on, resulting in wear and tear when the surface layer of the material is tired and damaged.

As mentioned earlier, adhesive wear occurs when smooth surfaces rub against each other in air or vacuum and in an environment without special corrosive chemical reactions, but the main cause of some adhesion wear is due to the fatigue and damage of the surface layer. Most of the time, we talk about fatigue wear and tear on the surface when rolling, similar to rolling bearings or gears.

Fatigue of plastic materials

The fatigue of plastic materials will be much more obvious than that of metal materials, because plastic solids are elastic, and they move relative to the rough protrusions on another surface, repeatedly, extrusion, compression, tensile stress, etc., until they are damaged in the elastic surface.

What is the difference between fatigue wear and adhesion wear?

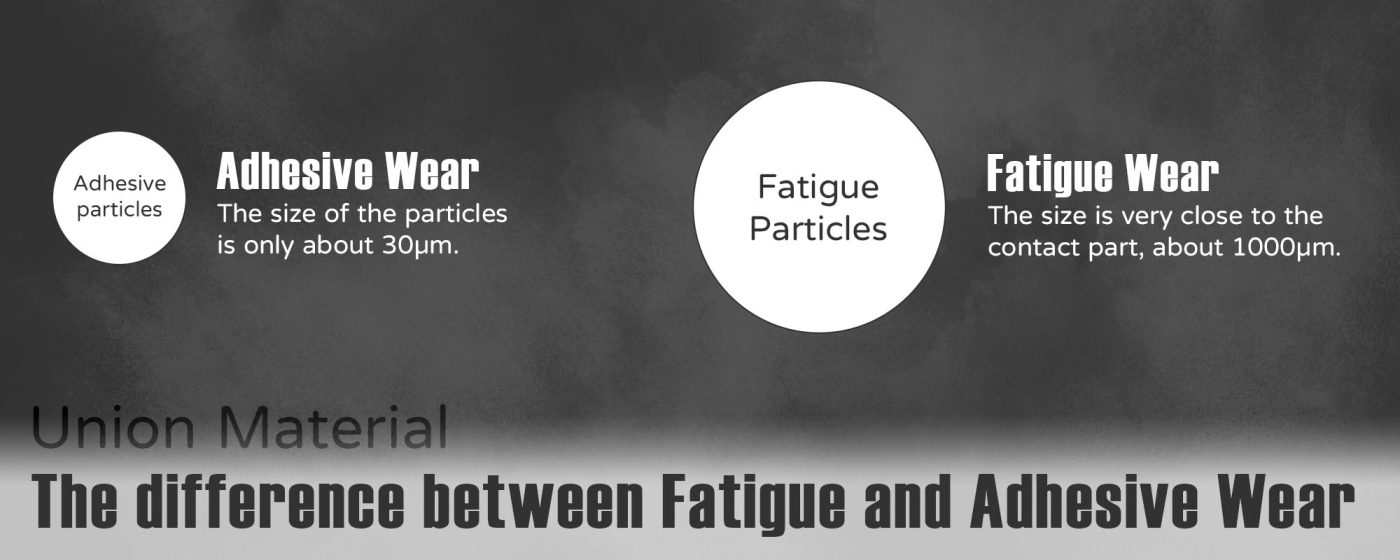

Fatigue wear seems to be a little similar to adhesive wear, but has different characteristics, as follows:

On the solid surface in the friction state, the abrasive dust removed is very large. The size of the abrasive dust will be very close to the size of the rolling contact part, about 1000μm. On the other hand, if it is adhesive wear, it is only 30 μm, so the size of the abrasion dust varies greatly.

In the experiment of measuring wear, all friction conditions are the same, and the friction value measured each time generally has a fairly obvious error. If it is adhesive wear, there is a difference of nearly 10 times between the maximum value and the minimum value. However, fatigue and wear are larger than those of adhesive wear, showing an error of about 200 times, which is not uncommon.

One of the engine life measurement methods, when changing the oil, the size of the wear particles in the liquid is observed, and the ratio of fatigue wear and adhesion wear is analyzed to evaluate the life of the engine (engine).

The effect of additives on fatigue wear

Sometimes, in order to prevent sticking or burning at the sliding contact site, various additives are added to the lubricating oil to reduce friction. These additives are prone to chemical reactions with metal surfaces and may contribute to increased life of sliding parts if they are adhesive wear. Fatigue wear is more likely to cause fatigue damage, resulting in shortened life.

Erosion and wear

The gradual loss of materials caused by the flow of the surface of the object or the impact of slurry containing solid particles is called erosion wear. In addition, if the liquid reacts chemically with the ground material and corrodes, the loss of the ground material may have both mechanical and chemical reactions.

Common examples include erosion wear and tear in pipeline bends, pumps, fan blades, steam pipes, and nozzles. Therefore, it is a widely encountered mechanism in industrial and power engineering. Due to the nature of the conveying process, the piping system is prone to wear and tear when abrasive particles need to be transported.

Types of erosion wear

According to external environmental factors, erosion wear can be divided into three forms:

- Solid Particle Erosion: Solid particle erosion is the loss of target material due to the continuous impact of solid particles in a flowing fluid.

- Liquid impact erosion: The liquid flow continuously impacts the surface of the material, causing liquid impact erosion.

- Cavitation Erosion: Vapor or gases in liquids can form cavities or bubbles, leading to wear.

In general, erosion wear resistance can be improved by increasing the hardness of the material or surface hardness, using appropriate materials, and proper product design. In addition, there are specific steps that can be taken to change the flow conditions, such as: reducing the flow speed of the liquid, eliminating turbulence in misalignments, and avoiding sharp curves.

The relationship between erosion wear and other wear

The occurrence of erosion wear may also lead to other abrasions, such as:

Causes scraping wear

This is caused when the eroded abrasive particles hit the surface at a small angle.

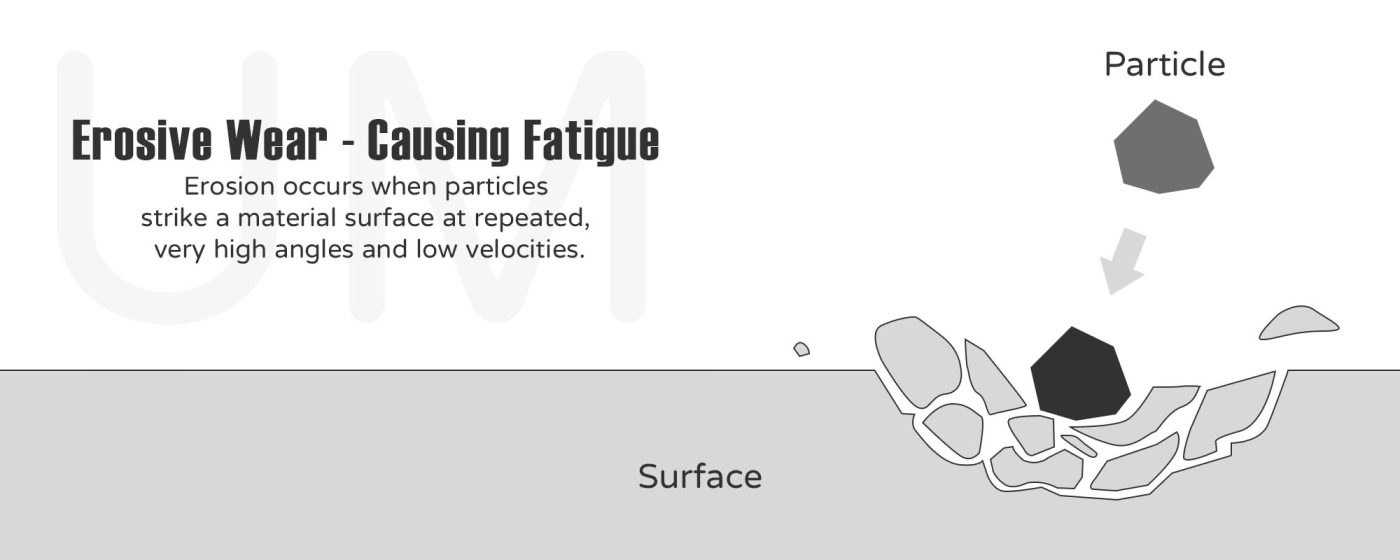

Leads to fatigue and wear

This is caused by the erosion particles hitting the surface of the material at repeated and very high impact angles and low velocities.

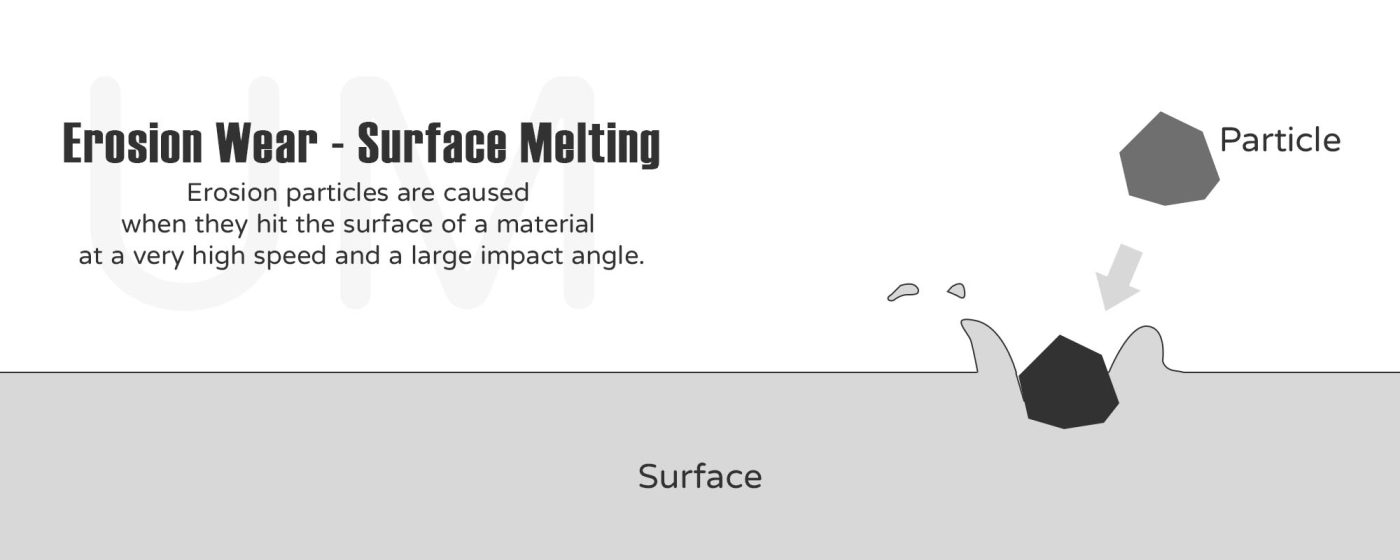

Causes surface melting

This mechanism is caused by the impact of eroding particles on the surface of the material at extremely high speeds and large impact angles.

conclusion

Understanding wear remains an active area of research in the hope that products will last longer, and delving into topics such as wear testing methods, the impact of microstructural properties on wear resistance, or the latest lubricants can provide additional insights. Every small advancement in understanding these mechanisms leads to more informed material choices and better-designed mechanical systems where even the tiniest interactions on surfaces can have a significant impact.