Bushings

Introduction to the bushing

UM bushing, the top and bottom are two circles of the same size, with uniform force and simple cylindrical appearance, in the part of mechanical engineering, in a wide range of applications, has become an indispensable key part, even if the appearance of other brands of products is the same, but compared with the performance and quality, we are still not inferior to them.

Using our UM’s proprietary formulation technology, the self-lubricating composite material gives the bushing a very low coefficient of friction, while significantly improving wear resistance and service life, allowing for long-term stable operation in a wide range of industries and achieving strength and rigidity comparable to that of metal.

Related Articles

Basic structure of the bushing

The bushing is an engineering ingenuity that combines simple design with functionality to help reduce costs. Its core purpose is to provide a low-friction sliding interface between the shaft and the hole, while absorbing vibration and protecting the mechanism. The following five points are the basic structure of the bushing:

Inner Diameter (ID)

In contact with the rotating axis, most of them still have very fine gaps, which require good surface finish and wear resistance. It can be designed with a smooth side or with lubrication grooves (grooves).

Outer Diameter (OD)

Press into the inlet hole to form a fixed fit, called interference fit. Some designs include external grooves to facilitate positioning, prevent displacement, or lubrication.

Height (H) or Length (L)

Determine the contact area of the shaft lining and the stability of the shaft deflection. Long or short can be selected according to the application requirements, which is generally proportional to the overall shaft length.

Wall Thickness (t)

Appropriate thickness affects the bearing capacity and shock absorption effect. Thin-walled design can reduce weight, but be aware of the risk of deformation; In addition, continuous increase in thickness does not mean that the bearing capacity can be continuously increased, unless there is a special purpose, excessive thickness is an unnecessary cost waste.

Chamfer (C)

Unified design, the top outer diameter is the guide corner, which helps to easily install into the hole; The bottom of the inner diameter is the guide corner, which helps to easily fit the shaft into the shaft liner.

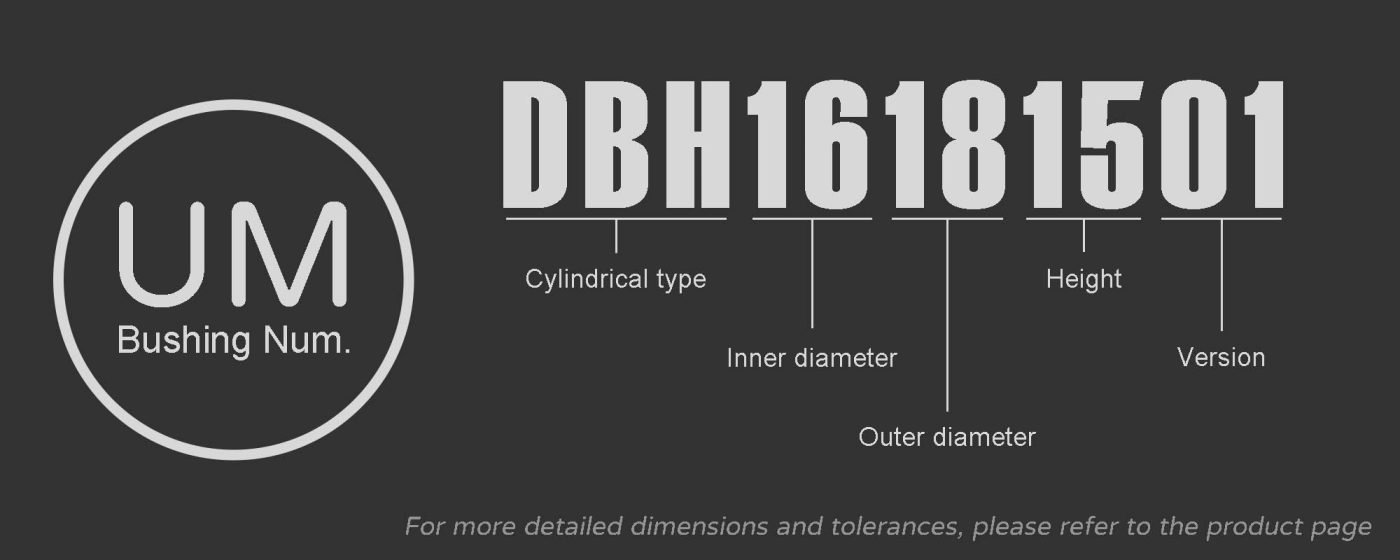

Numbering Description

We usually use numbers and words to represent the size of the bushing, similar dimensions, not necessarily every bushing is an integer. For example, for cylindrical bushings, you will see DBH as the beginning of the number. For flange type bushings, you will see DFB as the beginning of the number.

Then, the subsequent numbers represent the inner diameter, outer diameter, height, and version, for example, 16 in the DBH16181501 is 16 mm for the inner diameter and 18 is for the outer diameter of 18 mm. 15 is the height of 15 mm, and 01 is the version.

The values we provide are approximate and not integers, for example, 12 is likely to be 12.30mm. Therefore, you need to click on the link to enter the product industry to confirm the dimensions and tolerances in more detail.

Spec. Sheet

The current product specifications for all socket bushings in our online store are listed below. We offer several sizes to choose from depending on your design and usage. More products will be updated here.

If you can’t find the specs you need? They may just not be on the website yet. Please feel free to contact us and we will be happy to serve you.