Knowledge

Bushing Speed

Bushing Speed

Bushing Speed refers to the linear velocity achieved by the surface in the lining that is subjected to the movement of the object. Speed, expressed as the concept of time, is the distance traveled by each unit of time, is the English letter code capital V, the full name is Velocity, the size of the value expresses fast and slow, the larger the value, the faster it is, and the smaller the value, the slower it is. Another way to say it is Surface Velocity or Surface Speed.

Mode of operation

There are many situations in the application of the bushing, and the operating mode is mainly divided into three types:

- Reciprocation: The object moves back and forth in a straight line, or up and down in a straight line. It is commonly found in cylinders, shock absorbers.

- Rotation: The object rotates around the axis line, commonly found in wheels and motors.

- Oscillation: The object rotates around the axis line, and rotates clockwise and counterclockwise. It is commonly found in clocks and metronomes.

Compared with ball bearings, the speed of ball bearings sliding to the highest point is zero during the swing process, and it is also the point of lubrication interruption, resulting in material fatigue and wear, mainly due to the small contact area of ball bearings and extremely high stress. The self-lubricating bushing relies on internal lubricant to produce interrupted lubrication, and the contact area is large, almost completely sliding with the surface, and the final wear is minimal.

Basic formula

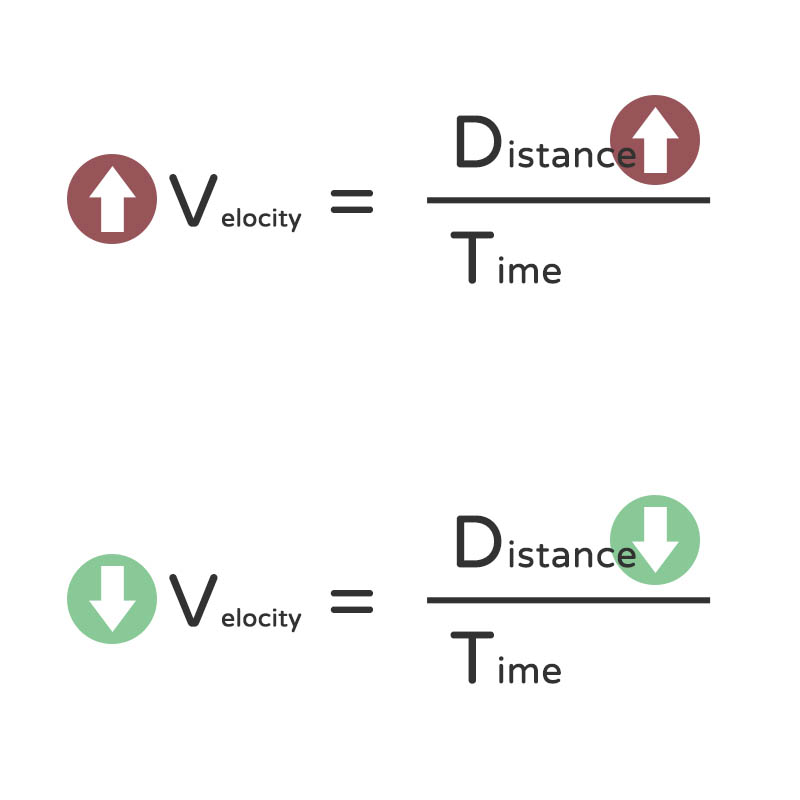

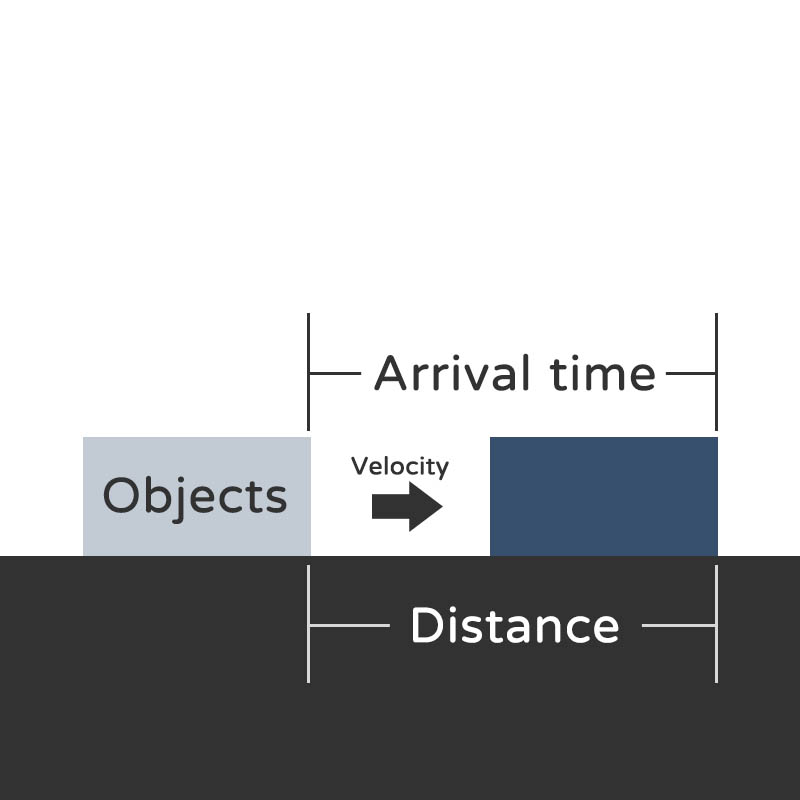

Speed = distance / time. Velocity = Distance / Time。 V=S/t。

There are many abbreviations for distance formulas, such as x, r, d, etc., here we mark it as S, because physics is commonly used, it can be understood as Span to take the first word S, in fact, you don’t have to care which letter to use, according to personal preferences and habits, because they are just a formula.

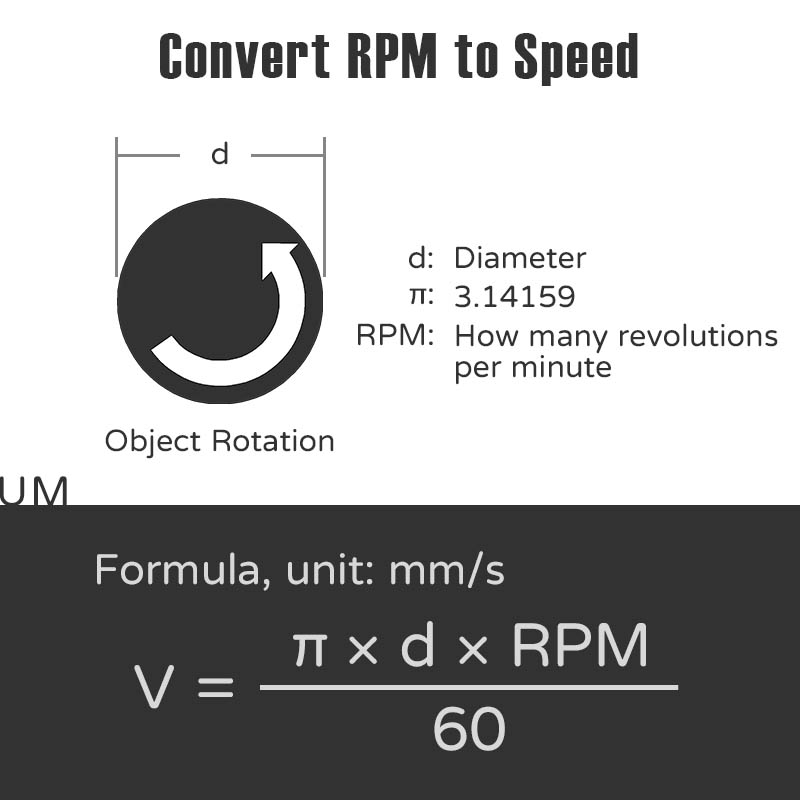

Rotational speed is converted to speed

Normally, the rotational speed, referred to as RPM, means several revolutions every 1 minute, that is, rev/min, first we have to find out what is the linear distance of a turn, then multiply by the number of rotations n, and finally divide by one minute equal to 60 seconds, so the circumference formula is the diameter of the circle multiplied by π=3.14159 to get the formula of π×d×RPM/60.

Unit

List some commonly used units

| mm/sec | mm/min | cm/sec | cm/min | m/sec | m/min | ft/min | |

|---|---|---|---|---|---|---|---|

| mm/sec | 1 mm/sec | 60 mm/min | 0.1 cm/sec | 6 cm/min | 0.001 m/sec | 0.06 m/min | 0.19685 ft/min |

| mm/min | 0.0166 mm/sec | 1 mm/min | 0.00166 cm/sec | 0.1 cm/min | 0.000016 m/sec | 0.001 m/min | 0.00328 ft/min |

| cm/sec | 10 mm/sec | 600 mm/min | 1 cm/sec | 60 cm/min | 0.01 m/sec | 0.6 m/min | 1.9685 ft/min |

| cm/min | 0.1666 mm/sec | 10 mm/min | 0.01666 cm/sec | 1 cm/min | 0.000166 m/sec | 0.01 m/min | 0.03280 ft/min |

| m/sec | 1000 mm/sec | 60000 mm/min | 100 cm/sec | 6000 cm/min | 1 m/sec | 60 m/min | 196.850 ft/min |

| m/min | 16.666 mm/sec | 1000 mm/min | 1.6666 cm/sec | 100 cm/min | 0.01666 m/sec | 1 m/min | 3.2808 ft/min |

| ft/min | 5.08 mm/sec | 304.8 mm/min | 0.508 cm/sec | 30.48 cm/min | 0.00508 m/sec | 0.3048 m/min | 1 ft/min |

The formula Calculation of the speed of the Bushing

The speed calculation of the bushing will be different due to different operating methods, and the<Actuation Method> whole calculation focuses on the conversion of distance, and the rotation mode is the distance per revolution, so it will be the diameter D multiplied by π; The reciprocating method is the distance of forward and backward movement, so it will be the distance S multiplied by 2; The concept of the swing is the same as the rotation method, but it is also multiplied by the swing angle θ/360. The detailed formula is as follows:

Bushing and flange bushings

Back and forth

Flange face, washer

What are the effects of speed

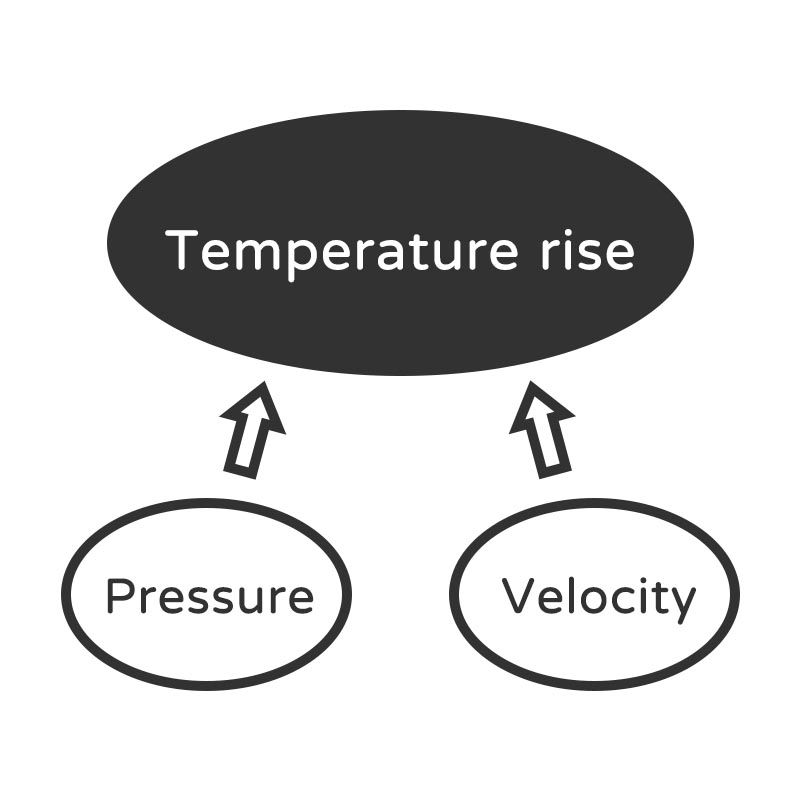

The speed of the bushing will directly affect the service life, and the pressure and speed will also affect the temperature rise, and the proportion of speed affecting the temperature is large, and the closer the temperature is to the melting point of the material, the faster the wear. The rise in temperature is closely related to the coefficient of friction, cooling, heat dissipation, etc.

The Effect of the Working Frequency of the Bushing

The operating frequency is roughly divided into three:

- Full-time operation: As soon as the machinery is running, the bushing will follow, such as the motor, or used as appropriate, such as the cooling fan. Since the friction temperature is continuously rising, it is harsh and unfavorable to evaluate the use of bushings, so careful and multi-party considerations are required in the design, and even the material limit PV value data and heat dissipation (heat dissipation) must be combined.

- Frequency operation: The bushing operation can be operated at a certain frequency, such as running for 1 minute/stopping for 1 minute. Because the bushing has a waiting and stop time, it is beneficial to evaluate the use of the bushing.

- Full time non-operation: The bushing operation time is almost zero, for example, the seat handle turns, when necessary, we will turn it or only turn occasionally, most of the time the bushing only carries weight, which is simple in evaluating the use of bushings.

How To Improve When It’s Too Fast

When it is used too fast, what are some ways we can improve it?

- Lube. Choose lubricants with low viscosity and high temperature resistance.

- Surface roughness

- Reduce the coefficient of friction

- Strengthen cooling and reduce the ambient temperature, such as turning on the air conditioner.

- The parts are selected with high heat transfer to increase heat dissipation.

- Change to a more high-temperature resistant material.

- Change to a material with a high PV value.

As mentioned above, both will generate heat due to friction, but the speed accounts for a high proportion, so the improvement of high pressure will be biased towards the load aspect, and the improvement of high velocity will be biased towards the surface contact and environment.