UM

UM, focusing on the design, manufacturing and production of polymer composite components with more than 30 years of experience, the initial business project is to manufacture various high-temperature, low-temperature, wear-resistant, conductive, antistatic, acid-alkali and other reinforced engineering plastic particles …….

How to work with UM? Process guidance

Create a win-win blueprint

Share successes and goals

When you have a need and need to further discuss cooperation with UM, you will roughly go through the following five processes, from the first contact to the cycle of reaching a cooperation as a guide, to help you save time and think about it for your reference.

1

Contact

- Fill out the contact form or add LINE

- Postcards or self-introductions

Find us through our website by filling in your contact information.

You can also join our official business account LINE: @dr.pulley.

2

Offer

- Provide information about your usage

You need to provide various detailed usage conditions, such as: engineering drawings, experimental methods, minimum purchase quantity, operating temperature, environmental conditions, hole material, roughness, etc.

3

Trial

- Sample testing

We can supply a small number of samples for you to test to ensure that the use meets your needs and is more secure.

4

Acquire

- Get a quote

The most important thing you care about is the price, and you will get a quote that may include the cost of the mold, how much the batch price, the lead time, etc.

5

Cooperate

- Reach a cooperation

If you are satisfied with our solution, in the end, both parties will fulfill their commitments and achieve the purpose of this cooperation.

Latest news

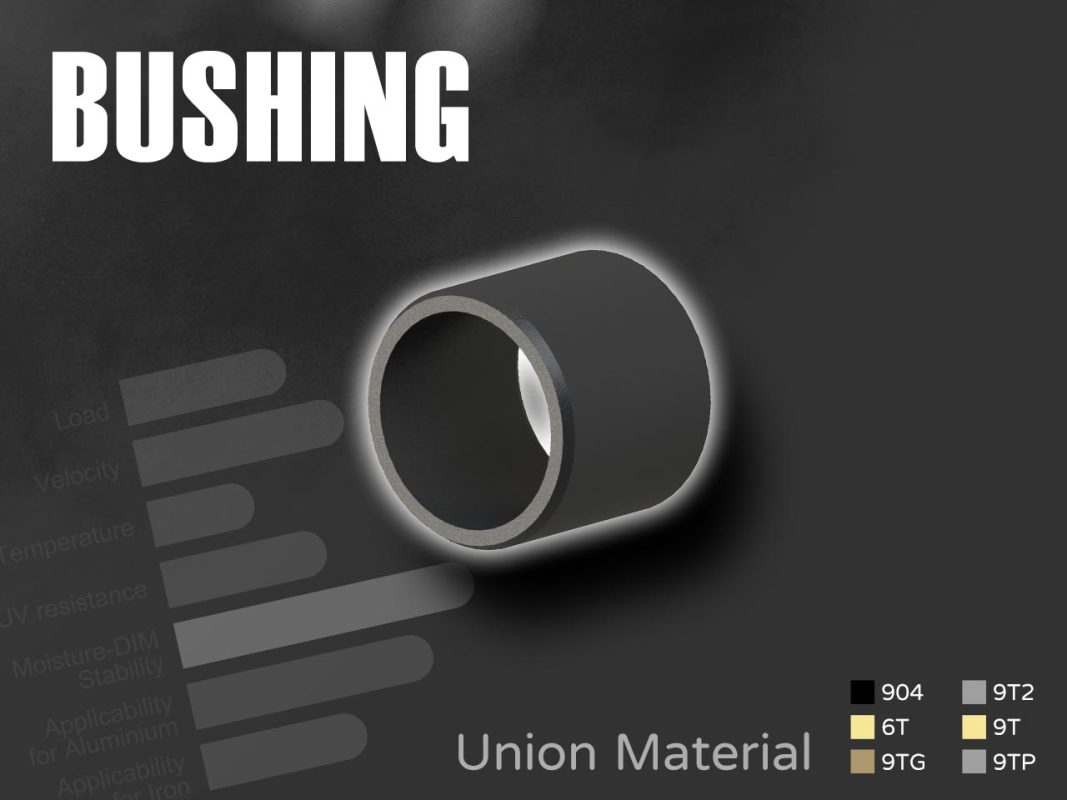

- Bushing SpeedUM Bushing Speed Bushing Speed refers to the linear velocity achieved by the surface in the lining that is subjected to the movement of the object. Speed, expressed as the concept of time, is the distance traveled by each unit of time, is the English letter code capital V, the full name is Velocity, the […]

- What are the types of wear, friction is briefly discussedUMWhat are the types of Wear? This article is more professional, share some of my own experience, because the wear and tear situation is quite complex, unable to be fully explained, and there is no standard answer, so it is for reference only. What you think is the general rule of wear and tear may […]

- What Is WearUMWhat Is Wear When two contacting solids move relative to each other, the surface material of the solids gradually decreases, and material loss occurs. This phenomenon is called abrasion, and some people call it wear. In most mechanical structures, there are parts with relative motion such as sliding or rolling. Since wear can determine the […]

- Bushing PressureUMBushing Pressure What is Pressure? Pressure, the force exerted from top to bottom, is the English letter code with a capital letter P, the full name is Pressure, so it can be interpreted as the force on the surface of an object in a unit area or a unit area or contact area, and the […]

Buy online

Self-Lubricating Bushing

- Cylindrical appearance for easy and quick installation.

- Emphasize oil-free, maintenance-free, and dry operation.

- Self-lubricating, wear-resistant properties for a longer service life.

- Provide a reference for the size of the hole and shaft matched by the bearing, and quickly browse and compare.

- Check the material properties online to quickly find the right solution.

- More than 20 sizes of bushings to meet the needs of all parties.

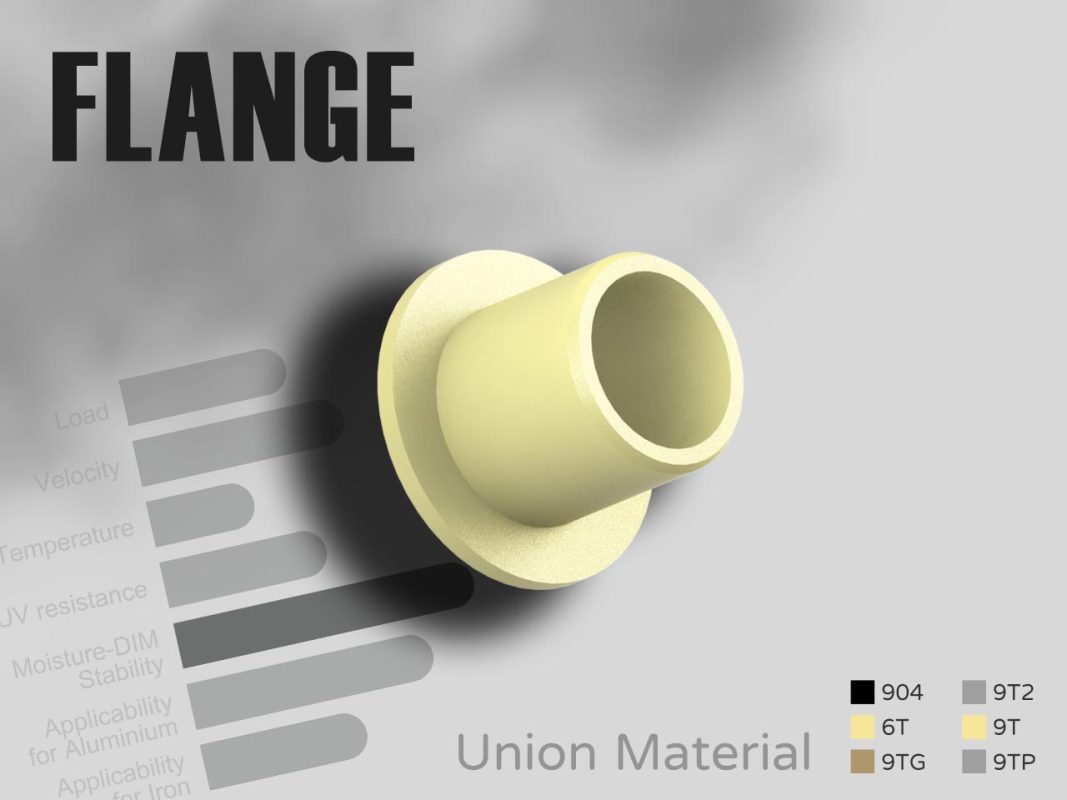

Self-Lubricating Flange Bushing

- With flanged edge shaft lining, it is loved by many users.

- Emphasize oil-free, maintenance-free, and dry operation.

- Self-lubricating, wear-resistant properties for a longer service life.

- Provide a reference for the size of the hole and shaft matched by the bearing, and quickly browse and compare.

- Check the material properties online to quickly find the right solution.

- More than 30 sizes of flange bushings to meet the needs of all parties.

Self-Lubricating Rods

- Use it through the processing of rods to shorten your product development timeline.

- Emphasize oil-free, maintenance-free, and dry operation.

- The processing size is flexible and the application range is wide.

- Check the material properties online to quickly find the right solution.

- More than 20 types of bars and 40 kinds of materials to meet the needs of all parties.